Connect with us

Follow us on social media

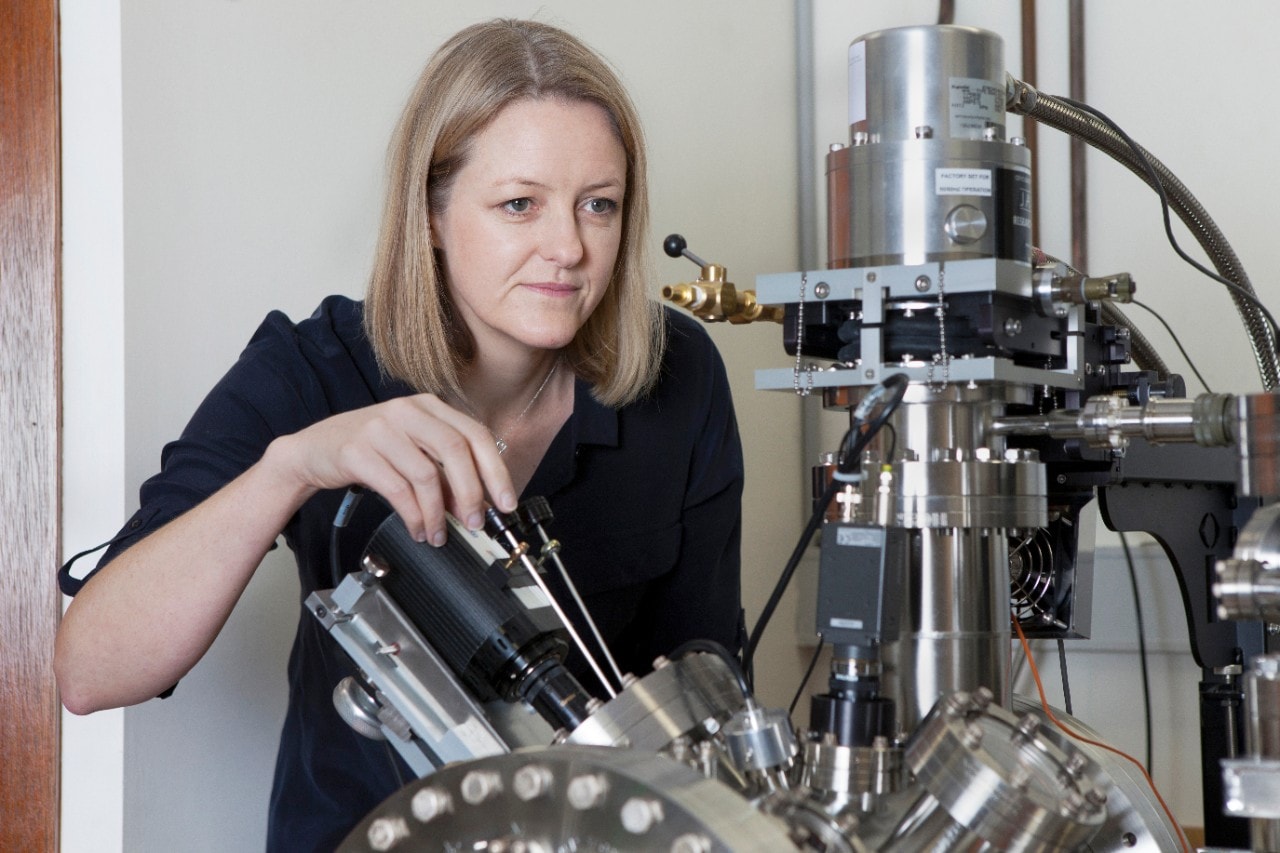

University of Sydney materials engineers Professor Julie Cairney and Dr Yi-Sheng Chen will collaborate with CITIC Metal on research designed to examine how hydrogen embrittlement occurs in steel.

Hydrogen embrittlement refers to the process by which certain metals become susceptible to early fracture due to the absorption of hydrogen.

“Hydrogen wreaks havoc in many alloys, leading to embrittlement that can cause catastrophic failure for any industry in which structures are exposed to this ubiquitous element,” explains Professor Cairney from the School of Aeronautical, Mechanical and Mechatronic Engineering.

“Unfortunately, comprehending the behaviour of hydrogen in these alloys is restrictive due to the actual difficulty of observing tiny, light and mobile hydrogen atoms.”

Professor Cairney and Dr Chen’s research project intends to explain where hydrogen goes in exposed high-strength steel by 3D-mapping the position of hydrogen atoms at the atomic scale within the alloy.

This imaging will be enabled by using atom probe tomography, a flagship microscopy technique housed within the Australian Centre for Microscopy and Microanalysis.

“Our research will elucidate how a proposed solution, hydrogen trapping, reduces hydrogen embrittlement, contributing to design criteria for hydrogen-resistant steels,” says Professor Cairney.

“We intend to replace the hydrogen with deuterium – the rarer isotope of hydrogen, which has an additional neutron and behaves similarly to hydrogen at atomic scale.

“It will also serve to remove any ambiguity caused by the ubiquity of background hydrogen signals within most analytical instruments.

“This sample will be kept extremely cold, so that the normally-mobile hydrogen and deuterium atoms stay in place for the atom probe experiment.”

For both researchers, understanding the distribution of hydrogen atoms in metals is an important first step towards ultimately designing hydrogen-resistant steels.

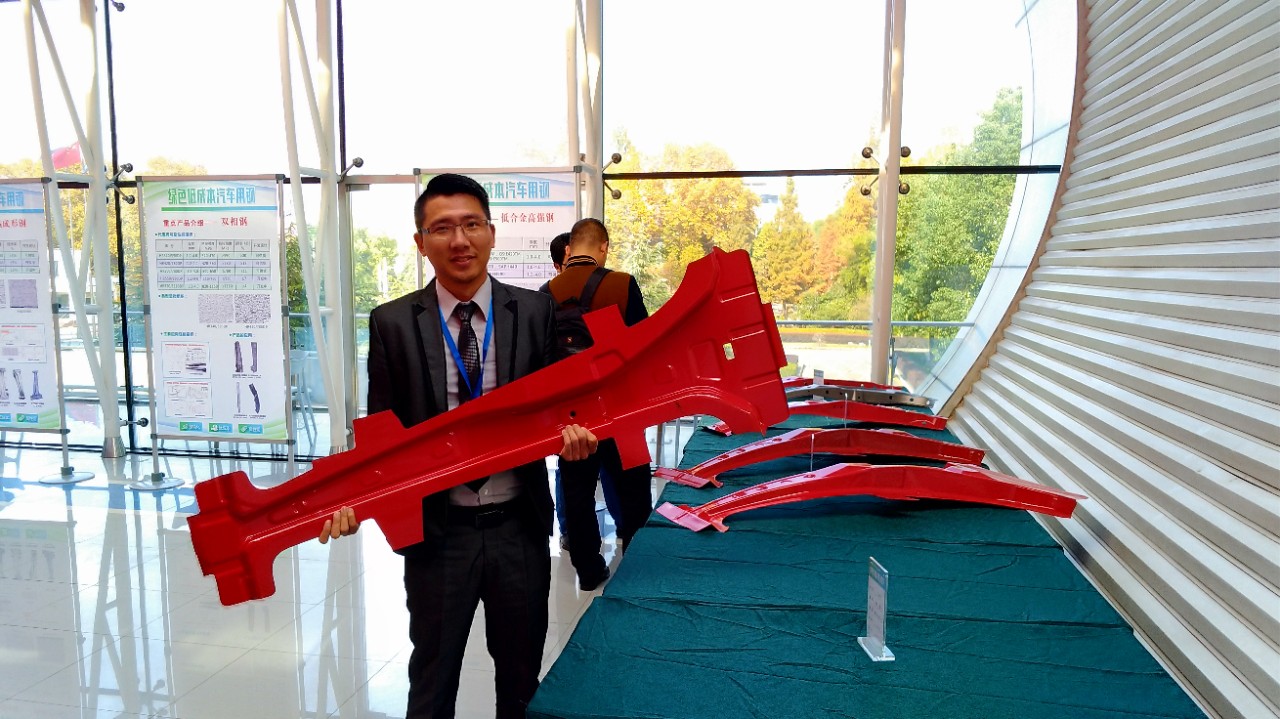

High strength hydrogen-resistant steels will allow lighter components for the automotive industry, which traditionally relies on heavier, thicker traditional steel components to produce the body and chassis of vehicles.

“Hydrogen embrittlement is one of the major limitations to the usage of steel material for fuel-effective light-weight cars,” explains Dr Chen, a University of Sydney Fellow also within the School of Aeronautical, Mechanical and Mechatronic Engineering.

“A vehicle made out of lighter components requires less energy during service, while offering the same levels of performance.

“However, the current susceptibility to hydrogen embrittlement means that steels possessing higher strength and a higher embrittlement risk are generally not considered in the design stage as it compromises safety.”

CITIC Metal, a supplier of niobium, will partner with both researchers on the project to understand the effectiveness of adding niobium to mitigate hydrogen embrittlement in high-strength steels.