Connect with us

Follow us on social media

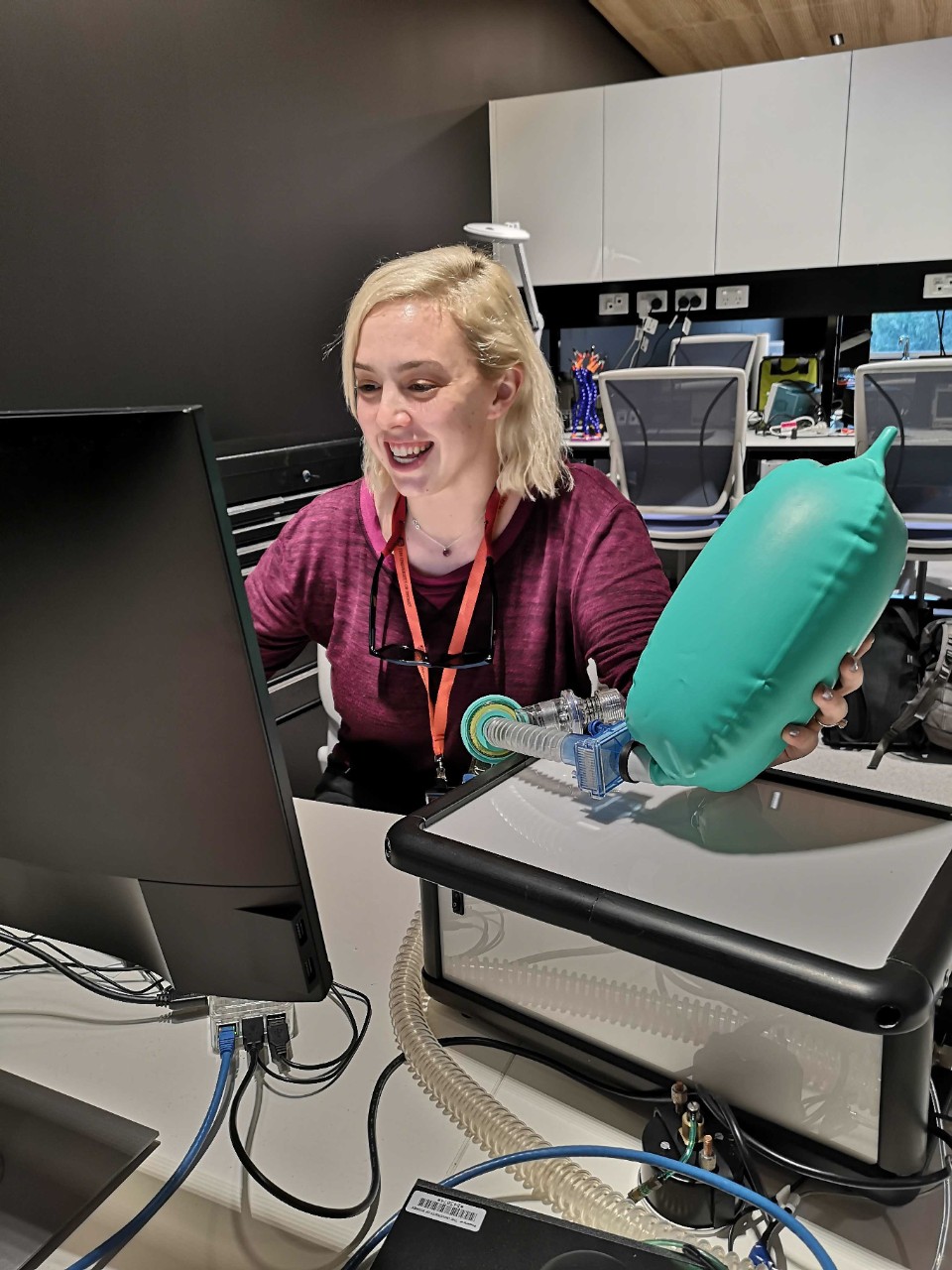

During the peak of COVID-19 in Australia, NSW Health put out a call to universities and industry to help design a ventilator that was low-cost and able to be manufactured locally. Professor Gregg Suaning from the School of Biomedical Engineering responded to this call and recruited a team of researchers and students to create a solution.

The first prototype, CoVida FC100, was successfully built in April. The team are currently manufacturing more models for further clinical assessment and Therapeutic Goods Administration (TGA) approval.

The CoVida project showcases the incredible work that is enabled by the University’s industry and government partnerships. It also sheds light on the types of real-life opportunities our students have access to – even in the midst of a global pandemic.

Members of the team included current students Jared Bergman, Claire Bridges and Daniel Landro who share their experience on the project.

A final year Biomedical Engineering and Medical Science student, Daniel Landro responded to Professor Gregg Suaning’s ‘call to arms’ because he knew it was time to do his part and make a difference.

What was your role on the project?

I have been working closely with the team to coordinate the mechanical engineering component of the project, focusing on reverse engineering existing designs and engaging NSW-based manufacturers to produce prototype assemblies.

The mechanical team would generate 3D models of various components and assemblies and prototype them using 3D printing technology in the School of Aerospace, Mechanical and Mechatronic Engineering Fabrication Laboratory. We would then work with manufacturers to produce functional prototypes. There is a long list of volunteers who did a lot of the hard work and made my role significantly easier, this really was a team effort.

What have you gained from this experience?

This project was a deep dive into a real, urgent public health problem that tested every lesson I had learned throughout my five years at university.

It challenged and developed my capacity for project management, leadership and problem solving yet reaffirmed my desire to make a difference as a biomedical engineer. I am proud of the work that our team has produced in response to the crisis and have learned a lot from the experience.

Claire Bridges undertook units from the Faculty of Engineering in 2014 as a study abroad student before later returning to complete a Master of Nursing and Graduate Certificate in Biomedical Engineering.

She is currently completing her PhD in cell-based therapies for diabetes under the supervision of Professor Peter Thorn.

This project is close to Claire's heart – a registered nurse herself and also engaged to an ICU nurse, Claire knew what healthcare workers would face if a lack of equipment became reality. It was important to her to prevent this and provide for the health workforce.

What was your role on the project?

I have been helping with the administration/external engagement side of the project – while we were all isolating in our homes, my goal was to keep volunteers engaged and to connect with groups outside of the University who were interested in what the team was creating. I’ve been fortunate to work with people to create our website, liaise with media groups, and try to promote the project as much as possible.

What have you gained from this experience?

It’s always great to learn from academics and industry professionals who are involved in the project – they know so much and can see applications of the theory we get taught as students, and provide insight to how best to take our learned knowledge and turn it into something useful for the real world.

I have definitely become more practiced at managing a group of people, delegating tasks and asking for contributions from people who are great in their fields. One of the most beneficial things to any project is collaboration from different backgrounds, and seeing clinicians, engineers, and students from all kinds of backgrounds come together has really highlighted the best ways to engage and connect with people.

A second project focusing on creating and providing PPE to clinicians has grown out of the ventilator project, and I was fortunate enough to be asked to be part of that team as well. It’s been a great opportunity to combine my clinical experience with my love of designing, improving, and building products, with a project-management element.

It’s been a great opportunity to combine my clinical experience with my love of designing, improving, and building products.

Jared Bergman, a fifth and final year Biomedical Engineering and Medical Science student put his hand up for this project because he was motivated by the immediate need for ventilators globally.

Whist the worst is over in Australia, this project will be crucial for facing future pandemics and other countries that are still battling to ‘flatten the curve’.

What was your role on the project?

I had multiple roles in this project. One role was working with the mechanical team by computer-aided design (CAD) modelling and 3D printing pneumatic components, as well as prototyping valves for these components.

Another role was working with the industrial design team in designing the user interface. I focussed on gathering information on existing systems, drafting user interface designs and working with other team members on developing the prototype enclosure for the ventilator. This was an iterative process which prioritised functionality and simplicity. This involved working closely with our resident clinician Dr Ken Harrison from CareFlight, as well as the mechanical and electrical teams to ensure all parts came together correctly.

What have you gained from this experience?

Working alongside students and staff from other faculties was a great experience since we were all working towards a common objective and trying to utilise whatever resources or skills we could. For example, students and lecturers from the School of Chemistry with past experience in industrial design were volunteering their spare time and dusting off old skills to help on the development of components like the housing prototype.

This project has helped me develop my knowledge of current skills like CAD modelling and 3D printing. I know much more about pneumatics and mechanical design than I did previously. Working with the industrial design team taught me new skills and showed me what it was like to work outside the field of biomedical engineering.

I was taught the steps and stages needed to develop a product from more than just an engineering point of view and enjoyed learning something different.

Working with other teams on a high stress project with limited time and resources meant teamwork, leadership and communication skills were crucial to making progress and ensuring all aspects of the project came together. I think these have been the most valuable skills I was able to develop over the course of this project.