Bottoms up to the future of nanotechnology

Sydney researchers are driving the design and development of nanowires forward, with new insights to improve the efficient and cost-effective production of these highly sought after building blocks of nanodevices.

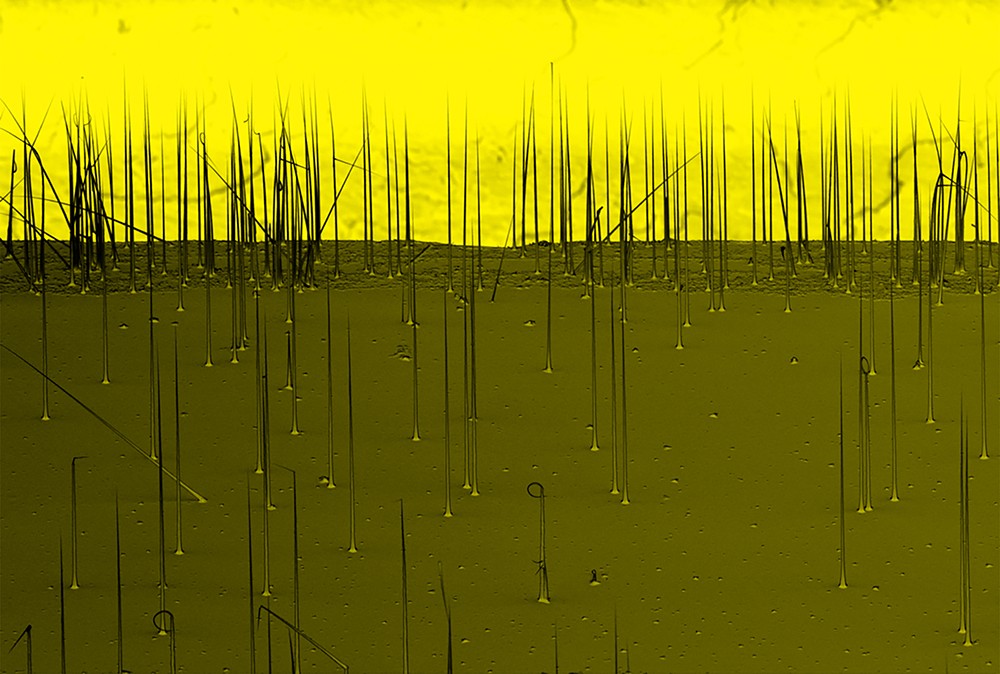

An image of free-standing InGaAs nanowires grown on a GaAs substrate taken with a scanning electron microscope at 2000x magnification.

"We now have the capability to grow nanowires that are several tens of nanometres in diameter, which is more than 2000 times thinner than a human hair.”

PhD student, Jiangtao Qu from the School of Physics is conducting ground-breaking research into these semiconductor materials that show some remarkable properties when they are grown at the nanoscale.

“Ternary InGaAs nanowires made from Indium (In), Gallium (Ga) and Arsenic (As) from the III-V group of the periodic table give us the freedom of tunability to grow complex structures for a range of applications.

“Nanowires can be functionalised and tailored in accordance with different requirements. For example, we can dope them with particular elements in the growth stage to change electrical properties, or change the growth conditions to vary their shape or size.”

Their semiconducting properties make them very useful for electronics, optoelectronics, thermoelectrics and photovoltaics.

We are aiming towards controlling the growth and properties of semiconductor nanowire technology.

Semiconductor nanowires are regarded as the building blocks for the future development of nanodevices.

“We are already benefitting from their adaptable properties and nanowire use is widespread in a range of applications. Nanowires are used to improve the performance of lasers and LEDs, they are used to make solar cells, we find them in computer processors, and they enable the storage of huge swathes of data,” Jiangtao said.

For most of these applications, the traditional method to make nanowires uses a top-down paradigm.

“A sophisticated photolithography technology is used to make nanowires on a silicon wafer via etching. The redundant materials in particular regions of the silicon wafer are removed, and finally a protected region will form nanowires.”

This is a costly method and it requires lots of expensive, advanced instruments to do the work.

“In contrast, the nanowires in our research are grown using a more economical bottom-up approach.

“Our method uses seeded particles on a semiconductor surface that can absorb elemental species from ambient precursors and precipitate them in the form of crystals at the metal/semiconductor interface.”

This method is termed the vapour-liquid-solid (VLS) mechanism.

“Free standing nanowires can be yielded and their position on the wafer can be determined by predefining the position of the seed on the wafer,” Jiangtao said.

Jiangtao Qu in his lab.

But why stop at the nanoscale when you can investigate every single atom on a nanowire?

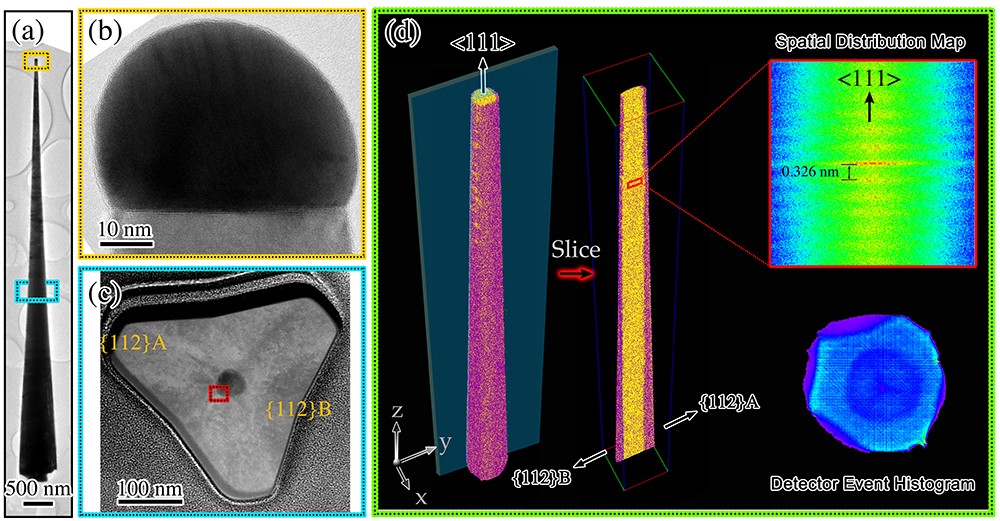

“We volumetrically mapped the elements and three-dimensional position of every atom of a single spontaneous core-shell InGaAs nanowire. To do this, we used atom probe tomography, which gives 3D tomographic images with each atom’s chemistry and position information at the same time.

“Our research revealed the behaviour of atoms of different chemicals during InGaAs nanowire growth,” he said.

(a) A single InGaAs nanowire imaged by transmission electron microscopy (TEM). (b) The metallic seed and its interface with the nanowire. This image is taken from the position of the yellow rectangle in image (a). (c) A TEM image taken from the position of the blue rectangle in image (a) showing that the cross-section of the InGaAs nanowire has a Reuleaux triangular shape. (d) Atom probe tomography analysis demonstrating the core-shell structure of InGaAs nanowires. Each purple dot is an Indium atom and each yellow dot represents a Gallium atom.

Jiangtao’s PhD research is co-supervised by Associate Professor Rongkun Zheng and Professor Simon Ringer of the School of Physics and the Australian Institute for Nanoscale Science and Technology (AINST).

Associate Professor Zheng said, "A fundamental and quantitative understanding of the growth-structure-property relationships at the atomic-scale is central to understanding where the use of nanowires will exhibit clear advantages.

“We are aiming towards controlling the growth and properties of semiconductor nanowire technology. Our new knowledge will enable us to tailor and optimise the efficient growth of nanowires for specific applications,” he continued.

The world is our oyster for what those applications can and will be, particularly for nanoelectronic technologies.

“Nanowire research is one of the most active areas of research in the nanosciences. We are certainly working in accordance with the predictions of Moore’s Law, which suggests that the number of transistors in a dense integrated circuit doubles every two years. Our devices are getting smaller and smaller and the capabilities of these devices are becoming more sophisticated.

“With this new research, we are making headway into producing nanowires more efficiently and economically,” Rongkun said.

Professor Simon Ringer, the Director of Core Research Facilities at the University of Sydney added, "These unprecedented 3D insights into nanowires enable a deeper understanding of nanowire growth and their growth-structure-property relationships.

"This is a marvellous scientific achievement that places the University of Sydney uniquely at the forefront of III-V semiconductor nanowire design and development.

“These materials will be driving all sorts of nanoelectronics technologies into the future."

This research, which appears in Advanced Materials was conducted jointly with the School of Physics, AINST, the Australian Centre for Microscopy and Microanalysis, the Australian National University, the Australian Nuclear Science and Technology Organisation and National Computational Infrastructure.