Plasma coating developed to decrease bone implant rejections

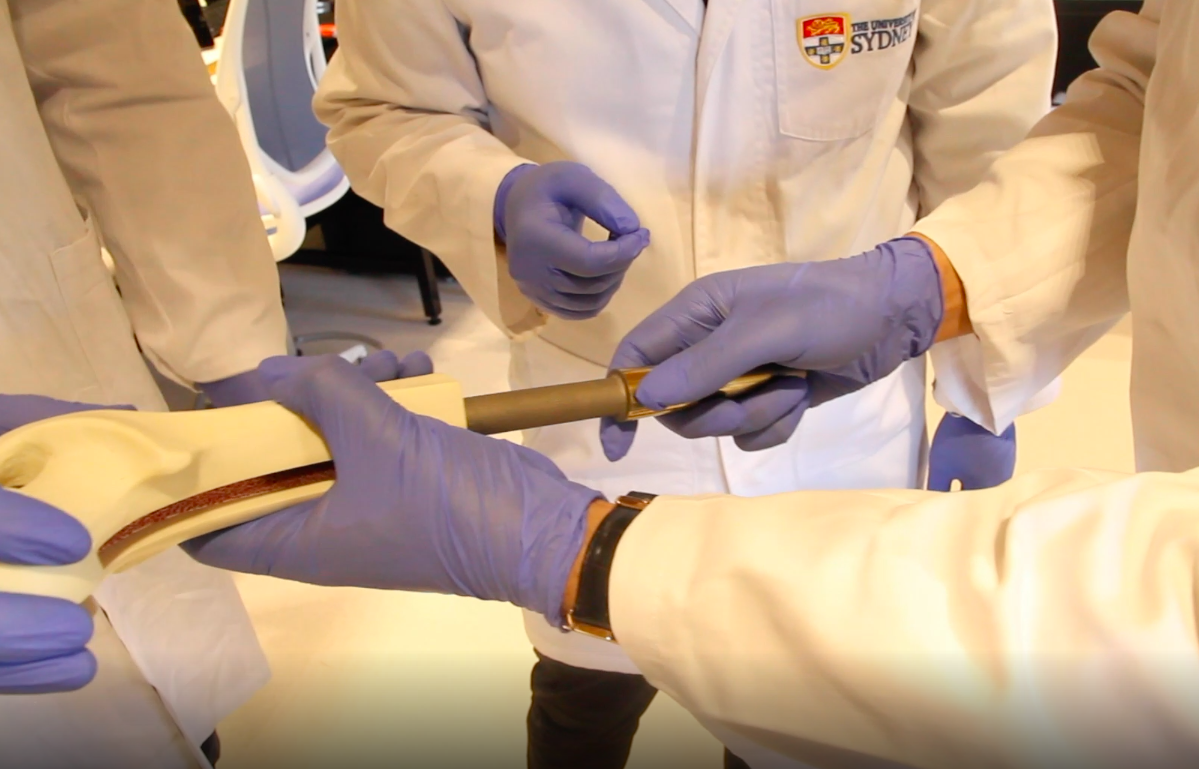

Dr Behnam Akhavan has developed a plasma coating for bone implants. Credit: Dr Behnam Akhavan, University of Sydney.

An international research project, led by the University of Sydney’s School of Aerospace, Mechanical and Mechatronic Engineering and the School of Physics in collaboration with UMC Utrecht and the Heart Research Institute and three other research partners, has developed a new plasma coating for bone implants with the aim of decreasing complications.

The new technology has been developed to help improve outcomes for patients by increasing the likelihood of an implant fusing to surrounding bone, and by reducing the chances of rejection or infection.

Published in Applied Materials Today, the study investigated the interaction of plasma-generated coatings with human-derived stem cells. It found that the new coating could enhance the functionality of bone-producing cells, allowing an implant to bind firmly to a host bone.

The paper’s lead author, plasma surface engineering expert from the University of Sydney’s Faculty of Engineering, Dr Behnam Akhavan says the results are promising and have led to in-vivo testing in the Netherlands.

“Our latest research presents great promise for the creation of a new class of robust, bio-active surfaces for orthopaedic implants,” said Dr Akhavan.

“Our latest research presents great promise for the creation of a new class of robust, bio-active surfaces for orthopaedic implants."

Titanium implants can be susceptible to bacterial infection. Photo credit: Katie Harkin/University of Sydney.

Despite medical improvements in surgical implant techniques and postoperative care, a significant proportion of orthopaedic implants fail due to infection or poor integration with surrounding bone tissue. Implant complications lead to revision surgeries that are risky, invasive and costly for the patient and healthcare systems.

The research team previously developed antimicrobial plasma coatings for implants to decrease complications from infection. However, failure to rapidly promote the growth of new bone on implant surfaces leaves them susceptible to poor fixation and loosening. The team’s current work tackles the problem of poor bone integration.

Australia’s ageing population has led to a rising incidence of osteoporosis-related bone fractures, bone cancers and joint replacement. Orthopaedic surgeries involving implants have increased, however many of these surgeries have had poor outcomes, as implants require firm bone bonding to be successful.

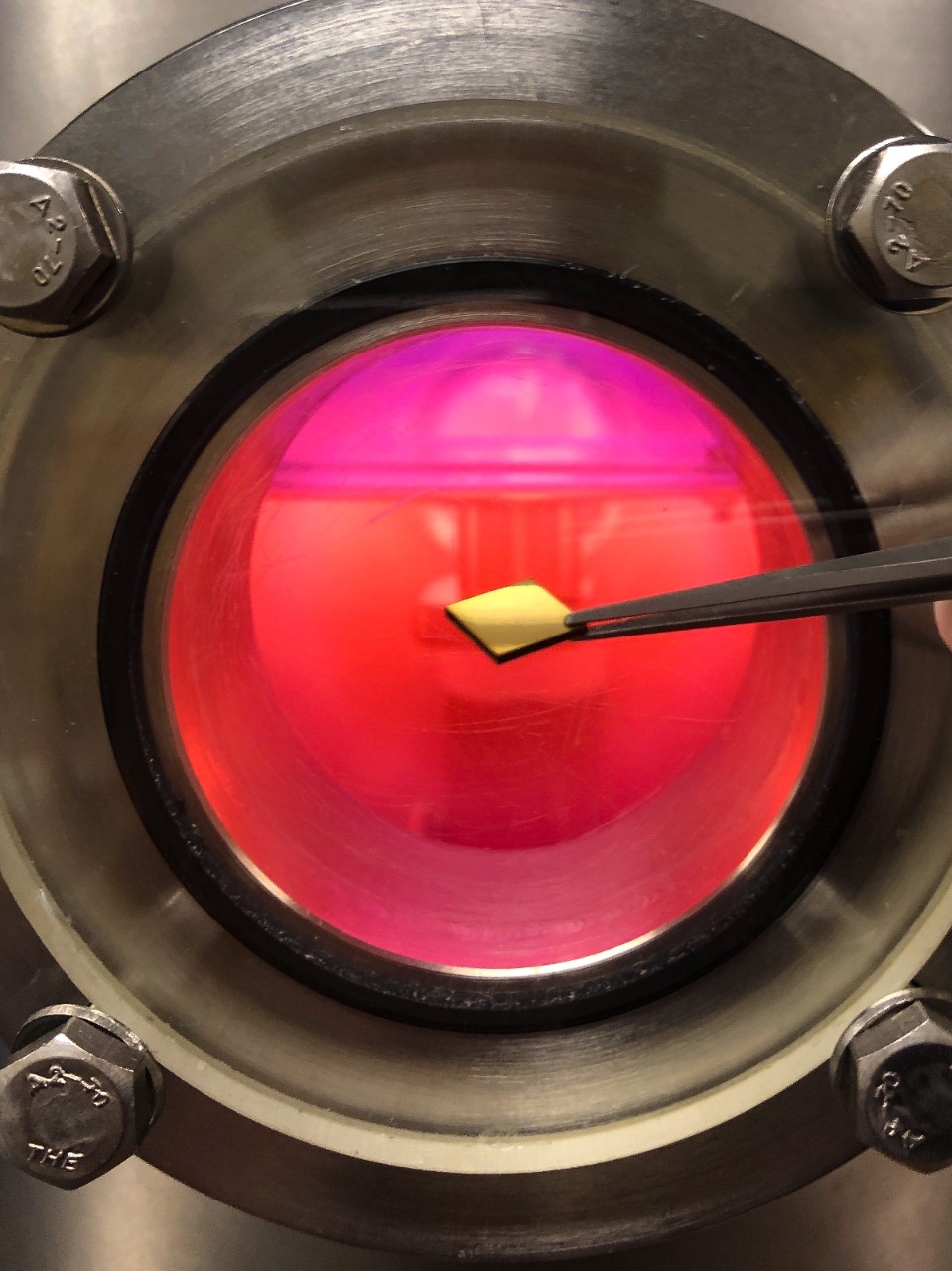

“We have developed a highly robust plasma coating from a mixture of low-cost argon, nitrogen and acetylene gas that is placed on the implant. Bone-signaling molecules are then applied to encourage stem cells to produce bone,” said Dr Akhavan.

The organic plasma coating works by 'shielding' an implant, so it is accepted by the body.

“The implants have been surface-engineered using the plasma technology and will be overgrown with bone-producing cells once implanted in the body, allowing them to firmly attach to bone tissue.

“The mechanically strong coating can remain on the implant surface for long durations, even if it is scratched during surgery. The bioactive molecule coating effectively ‘hides’ the metallic implant from the body, so it is treated as a biological structure rather than an invasion.

“Rapid implant integration reduces the chance of an implant loosening and failing, therefore eliminating the need for revision surgeries,” he said.

The research team, which includes Applied Physics and Surface Engineering academic, Professor Marcela Bilek, believes the application of plasma coatings on implantable devices is a viable approach to mitigating implantation issues by mimicking surrounding tissue.

“This coating is fully organic and is a significant advancement because it robustly adheres to titanium implants, while presenting strongly attached biological signaling molecules that guide tissue formation at its interface with the body,” said Professor Bilek.

Close to a million Australians have undergone a joint replacement surgery. Each year another 90,000 devices are inserted at a cost of around $1 billion.

Disclosure

The research, Radical-functionalized plasma polymers: stable biomimetic interfaces for bone implant applications, is a collaborative work by the University of Sydney’s School of Aerospace, Mechanic and Mechatronic Engineering, the School of Physics, the School of Civil Engineering, the Heart Research Institute, and the University Medical Centre Utrecht in the Netherlands.

This research was financially supported by Australian Research Council (ARC) and the University of Sydney Utrecht University Partnership Collaboration Award.