The biotechnology transforming crops for Australian farmers

By the time a farmer sees a disease outbreak in their crops, devastating financial and environmental consequences might already be unavoidable. If only it was possible to detect a plant pathogen before real damage was done. Well, now it is.

Founders of BioScout, (L-R) Lewis Collins, Saron Berhane, Henry Brindle and Josh Wilson, with new team member and current student, Jesse Morris.

In 2015, a farm in the heart of Australia's largest banana region had an outbreak of a destructive soil-borne fungal disease called Panama Disease.

For banana growers, this disease is up there, crisis-wise, with bird flu and Ebola. With far north Queensland accounting for 85 percent of Australian banana production, it was a terrifying moment for the industry.

Panama Disease, aka Fusarium oxysporum f. sp. Cubense tropical race 4 (TR4), or Fusarium wilt to its very few friends, struck Australia in 1997 when an outbreak in the Northern Territory decimated commercial banana growing in the region.

The disease is a formidable foe, but new technology from a team of enterprising engineers, who met as students at the University of Sydney, is set to help farmers detect, map and eradicate it before it spreads.

In classic superhero tradition, the squad of four is a super nerdy, diverse bunch of high achievers, each with a distinct set of strings to their bows, aside from engineering.

Saron Berhane (BE(Hons) '18 BMedSc '18) is a microbiologist (and event co-ordinator and photographer); Lewis Collins (BE(Hons) '17) is proficient in robotics, mechatronics and biomedical engineering (he also hikes and has a drone obsession); Henry Brindle (BE(Hons) '19 BCom '19) is a mechanical and hardware engineer with a collection of self-built 3D printers; and Josh Wilson (BSc '18) BE(Hons) '18) is a computer scientist, engineer and mathematician, who solves complex computer science and maths problems for fun.

With such an embarrassment of skills, it’s little wonder their plant disease-detecting brainchild, BioScout, hit the ground running, with the test deployments starting in July 2017, and commercial installations from April 2019, only three years after development began.

There's this huge digital revolution happening. But there's a gap in what's happening in the air around us, in the disease base. And we're hoping to answer that part of that equation.

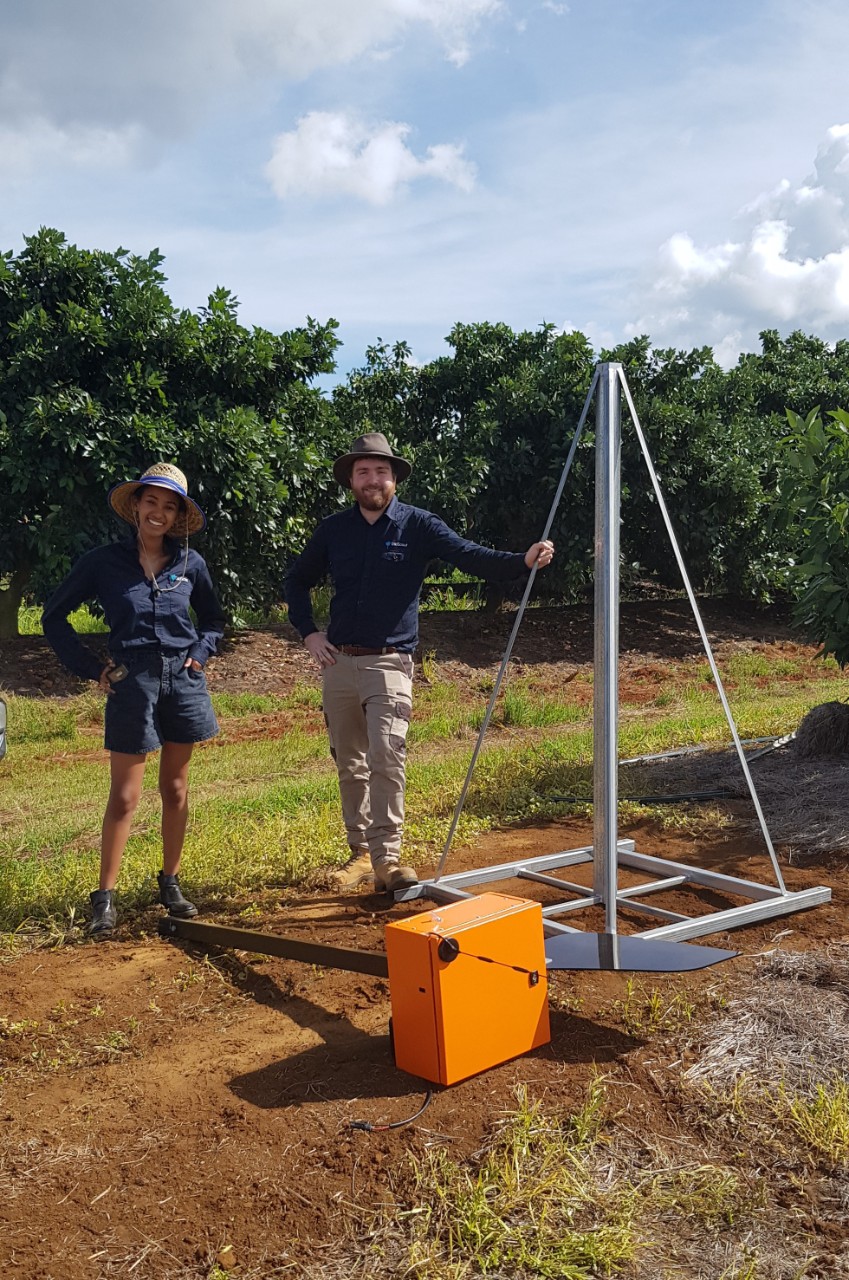

Berhane and Lewis installing BioScout in the field.

The BioScout platform consists of patented sensors that suck in air and analyse spores and other airborne particles onsite, with alerts sent to the farmer via text message. An online dashboard shows atmospheric conditions and disease patterns in real time across farms or whole regions, so the farmer can make decisions about when and where to spray.

“So, a farmer can say, its 27 degrees, 90 percent humidity and there's a spore load that's increased over the last two days. If I don't spray right now, we're going to have a disease outbreak which is going to be very severe,” says Collins.

BioScout had a major coup earlier this year, when the team secured a trial with one of the major banana growers in Far North Queensland. The trial is in a district where four other farms are infected with the previously mentioned Fusarium wilt, which spreads by root contact and by fungal spores in soil and water. This means their banana-grower client is on constant high alert for outbreaks, with stringent biosecurity measures and monitoring.

During a three-month trial covering a 15-hectare test plot, BioScout’s constant monitoring meant four fewer sprays were done. A generalised reduction in spraying like this would mean a significant cost saving for the farmer, plus the potential to dramatically reduce the chemical load in the environment, and indeed, the fruit produced. Usefully, the sensors can also indicate if a spray has been ineffective, allowing the farmer to spray again to retain a higher yield.

“This is the last digital frontier for agriculture,” Collins says. “You can already look at soil moisture and use irrigation, and tractors can drive themselves – there's this huge digital revolution happening. But there's a gap in what's happening in the air around us, in the disease base. And we're hoping to answer that part of that equation.”

During his studies at Sydney, Collins was working on a PhD about how to detect the spread of wheat rust using drones and unmanned aerial vehicles, when he was joined by honours students, Berhane and Brindle, in 2017.

Berhane remembers how well they complemented each other. “We were basically working on different aspects of the system. I was looking at the healthcare application and building the analysis hardware, while Henry was looking at the actual sensor unit and how that would be mechanically engineered to detect pathogens and spores,” she says.

“Halfway through that year, we realised this sort of technology doesn't exist anywhere on the market. The only thing close to it was about 50 years old and hadn’t been changed or updated in that time.”

BioScout analyses airborne spores and alerts farmers via text message.

Crucial to their success has been the business development programs they undertook. In 2018, they completed both the University of Sydney's Incubate and Inventing the Future programs and took part in the very competitive national Startmate Accelerator in 2019.

The programs helped the BioScout team rapidly apply their research into different markets, as well as building business skills and providing an opportunity to meet top venture capital firms, funders and farmers. Collins and Berhane also had to develop their public speaking skills, as large-scale presentations can be an important part of the process. Meeting prospective clients was also of huge value.

“After talking to farmers and agronomists, we realised that drones aren't quite ready for mass deployment in agriculture, because you need a pilot’s license to fly them and you can't fly beyond the line of sight. So we actually pivoted the technology to what it is now – a static unit that sits on a rotating axis on a pole. It's such a good example of pivoting that they actually now teach it at the Business School,” Collins says.

BioScout is seeing healthy growth, with three farms taking on the technology this year alone, and another 29 farmers in Australia and three in the United States keen to deploy the technology in 2020. The team are currently looking to raise funds so they can commercialise the technology further and ultimately make BioScout ready for scaling up.

“From idea to even starting to commercialise takes the average piece of agricultural technology 10 years. So, farmers are always surprised that our turnaround was so quick. For me, it's a great chance to show that the University and students can work together to build something pretty amazing,” Collins says.

With the BioScout able to analyse thousands of airborne particulates like pollen, microorganisms and environmental toxins, a plethora of healthcare applications for hospital- acquired diseases, asthma, allergies and disease management looks likely in future.

It’s still early days for BioScout, but the fast uptake of the technology shows that when good ideas and great research are developed hand-in-hand with end users, world-shaping outcomes are possible.

Written by Rebekah Hayden for Sydney Alumni Magazine. Photography by Louise M Cooper.