Female led industry and research collaboration leads to long term partnership

The benefits of collaboration between industry and academia are invaluable. Industry gains by having access to extremely expensive resources and technology, specialist knowledge and skills, and access to specific resources and licenses required to conduct certain experiments. Universities profit by having opportunities to address real-world questions with targeted solutions, and a path to translation or commercialisation.

Dr Elizabeth Clarke, who has ten years’ experience designing and conducting biomechanics research, is the director of the Murray Maxwell Biomechanics Laboratory, a biomedical engineering based research group. The Lab’s NSW Health anatomy licence paves the way for a wide range of research projects in cadaver tissue, and orthopaedic device companies can access these unique spaces through collaboration with the University.

“Industry will have a specific question, or a need to validate or test a new device or technology,” says Elizabeth, “and I can design the experiment with resources, equipment and technology that industry doesn’t have.”

Elizabeth initially interacts with companies on consultancies or contract research and some of these lead to long term partnerships. One pilot project three years ago with Allegra Orthopaedics and Bone Ligament Tendon (BLT) paved the way to a 3 year collaborative grant worth $2.4M through the Innovative Manufacturing Cooperative Research Centre (IMCRC).

The project is developing innovative manufacturing technology within Australia for 2 novel medical devices. “This gives you an idea of the pathway to long-term partnerships with university and industry,” she says.

“If a company has a problem, you can do a small study and off the back of that, progress to partnerships with long standing multimillion dollar projects.”

Dr Elizabeth Clarke with a robot from the advanced robotic simulation facility.

Elizabeth is also establishing an advanced robotic simulation facility in her lab, with five industry partners, including NSW government and NSW Northern Sydney Local Health District.

Their collaboration is establishing a facility worth $450,000. Hospitals such as the Royal North Shore and industry partners are involved in regulatory testing and validation for devices and orthopaedic surgery planning.

This robot has brought expensive and time-consuming testing, normally conducted overseas, to an accessible location. Industry can run their research on their own schedule, access local collaborators and expertise, with ongoing interaction, without incurring expensive travel costs.

Elizabeth successfully circumnavigated the complications between industry and the often-fraught bureaucratic world of tertiary education. “Industry works on different timelines,” she explains. “The partners want things done immediately.” But researchers strive for a perfectly designed study before the results are even published. “Contracts need to be signed quickly,” she adds, “and procurement cannot take two weeks.”

Likewise, the challenges for researchers are not immediately obvious for industry. “They don’t understand my time is not free. It is paid for by a research grant. It takes a lot of expertise and skill which is why university salaries are much higher.” A researcher's reputation, which rests on the results of a study, can attract more grant funding and increase their profile significantly.

Industry can claim tax incentives and have access to government funding opportunities that match the industry funding schemes.

Elizabeth has enjoyed strong support and encouragement from within the University despite the barriers of being a female researcher in academia. “My boss and I have long discussions on who should appear first in a grant application. He is a huge supporter of gender equity but in reality, he has a better CV, due to my age, position, career breaks and therefore number of publications,” she adds. “We decided in my family that I would be our children’s primary care-giver. That means I cannot work a 60-hour week.”

Elizabeth has experienced no setbacks as a woman working with industry, and also collaborates with women enjoying leadership positions within those companies. “I was heavily pregnant when I met our partners from Allegra Orthopaedics and BLT for the first time. They didn’t bat an eyelid, signed the contract and I did the research before the baby arrived. This led to the $2.4M grant and ongoing partnership,” she adds. “If there is trust, it will lead to a long lasting collaboration.”

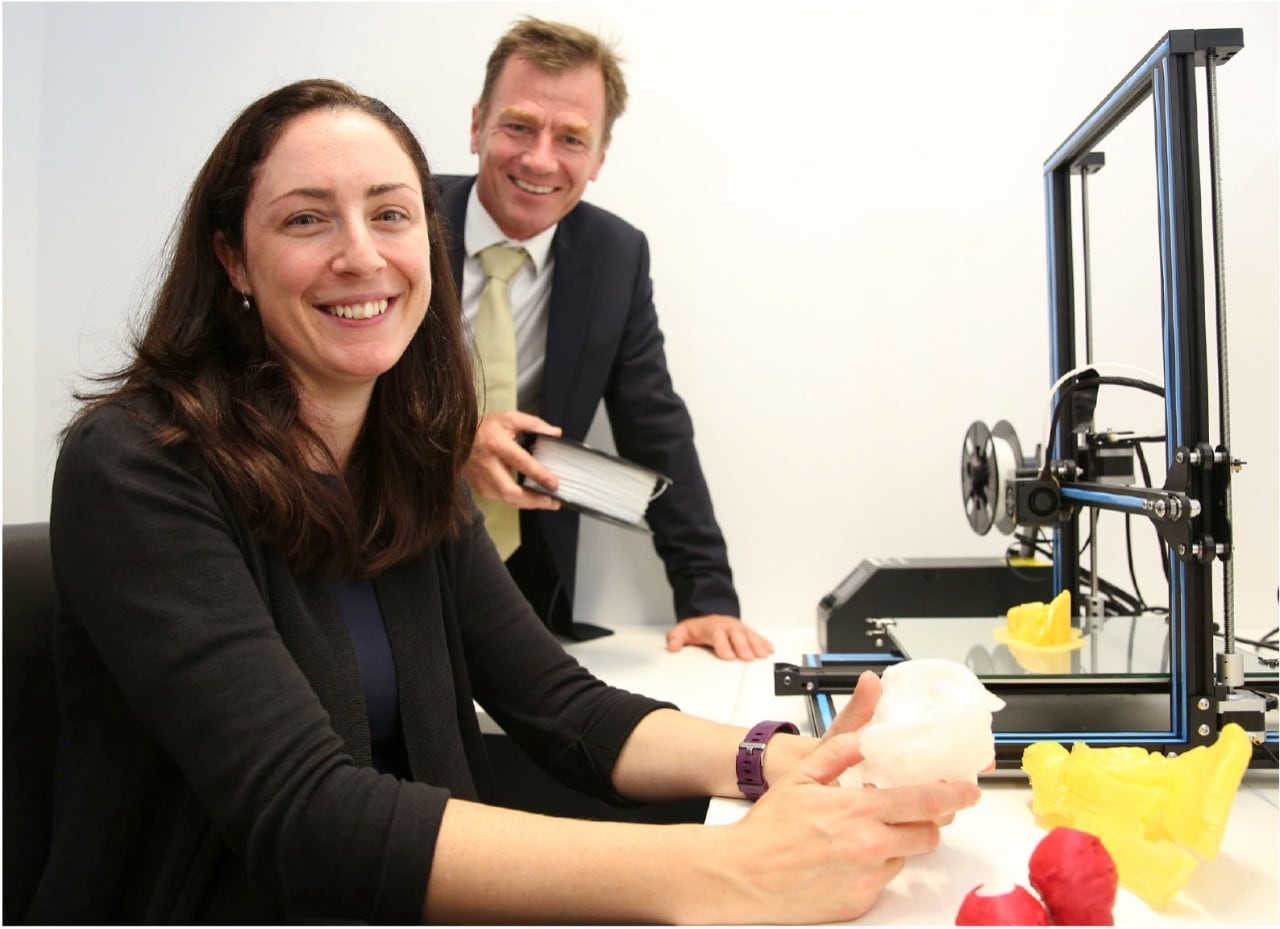

Dr Elizabeth Clarke and Professor Bill Walter.

Companies need exposure in conferences and in journals to promote their products. “The advantage of working with Liz and I is that companies get inroads into recognition that they would otherwise not have,” says orthopaedic surgeon, Professor Bill Walter whose research is published in peer reviewed international arthroplasty journals.

Allegra Chief Executive, Jenny Swain, said: “We believe our collaboration with BLT, Sydney University and the IMCRC will see Australian companies achieve considerable recognition for our innovative capabilities.”