Passing the acid test: low-pH system turns CO₂ into products

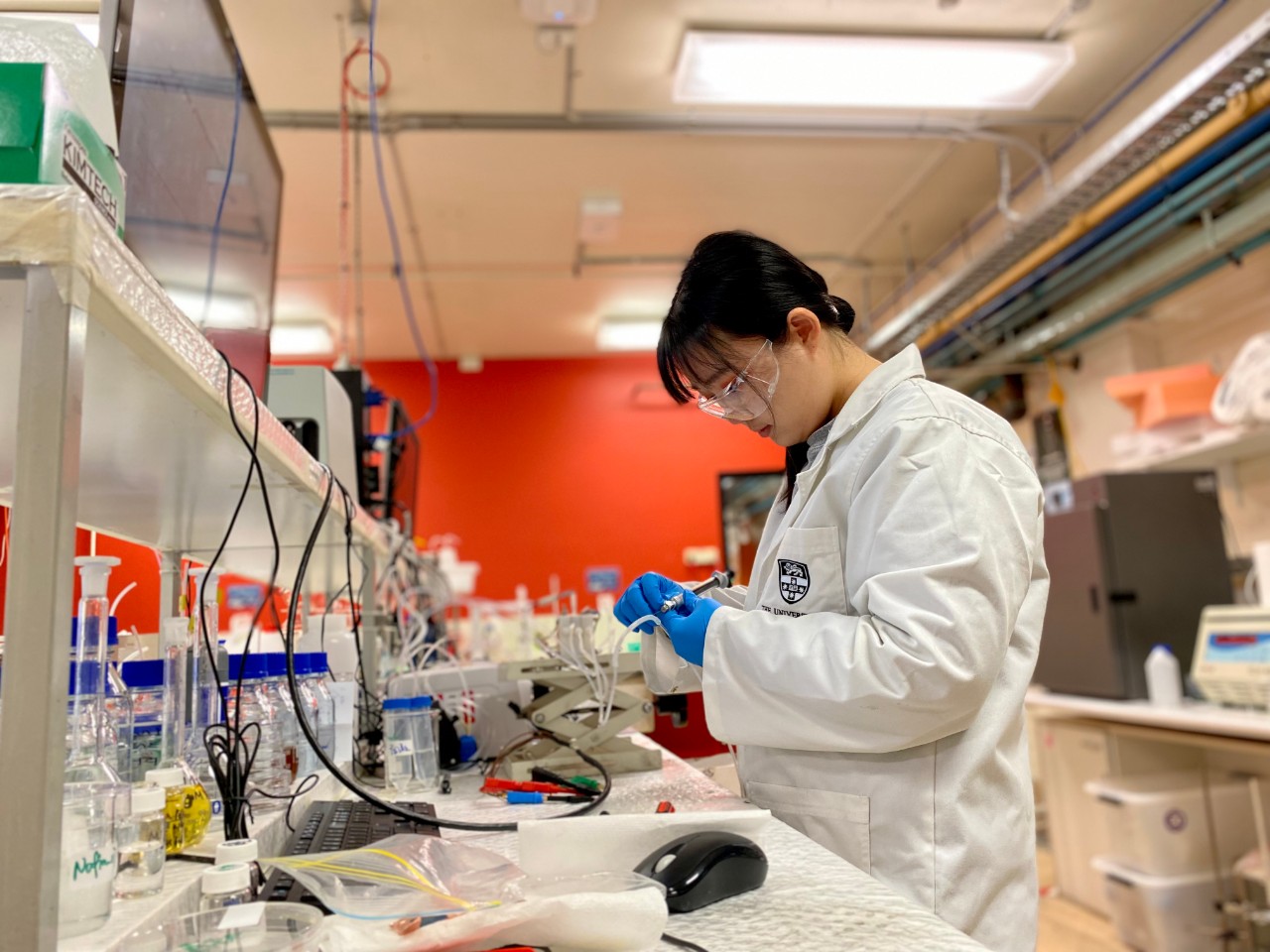

PhD candidate, Ms Shuzhen Zhang, who contributed to this project, samples the outlet stream from the electrochemical reactor for product analysis. Credit: University of Sydney.

An engineering researcher from the University of Sydney, in collaboration with a team at the University of Toronto, has developed an electrochemical system that coverts a greater amount of carbon (CO₂) into valuable products.

The International Energy Agency recently cited carbon capture and storage as a strategy that can help keep global emissions low enough to limit global warming to 1.5°C by 2050. However, captured carbon currently has little economic value, reducing the incentive for companies to invest in this technology.

The team of researchers has addressed this challenge by designing advanced electrolysers – machines using electricity to convert captured CO₂, plus water, into the building blocks of common everyday materials, from plastic to lycra. This helps create a market for captured carbon, while also providing a low-carbon alternative to fossil fuel-based manufacturing processes used today.

Unlike previous systems, the team’s latest design can be run under strongly acidic conditions, which reduces undesired reactions and enhances overall efficiency.

“Our research differs to previous approaches. Instead of choosing between an efficient use of electricity or efficient use of carbon, we do both

“Our research differs to previous approaches. Instead of choosing between an efficient use of electricity or efficient use of carbon, we do both,” said Dr Fengwang Li, from the University of Sydney’s School of Chemical and Biomolecular Engineering.

“This electrolyser enables the creation of high-value products such as ethylene.”

Ethylene is the most commercially produced organic compound in the world, used across many industries, including in metal fabrication and the manufacture of medical devices.

Dr Li and the team's electrolyser utilises captured CO₂, which flows over a solid catalyst through which electricity is supplied.

“Previous systems operated in alkaline or neutral conditions, meaning most of the CO₂ was wasted, and would be converted into carbonate instead. By contrast, our process, using high acidity, retains CO₂ at rates of up to 70 percent,” said Dr Li.

The researchers say while the carbonate can be extracted, converted into CO₂ and fed back into the electrolyser, doing so is energetically costly. The team’s calculations show more than half of the energy consumed by the overall system would be spent on recycling the carbonate in this way.

More acid, more (fixable) problems

Running the electrolyser under low pH, or acidic, conditions prevents the formation of carbonate but introduces a different problem: hydrogen ions in the acidic solution get converted to hydrogen gas, leaving few electrons available to combine with CO₂.

The team dealt with this problem by combining two strategies. First, under acidic conditions, they increased the electrical current, flooding the reactor with electrons. Hydrogen ions rushed in to react with them, but got caught in a molecular traffic jam, a technical term called mass transport limitation.

“In effect, we’re creating a reactor that is acidic throughout, except for a tiny layer within less than 50 micrometres of the catalyst surface,” said co-author and University of Toronto researcher, Haoming Erick Huang. “In that specific region, it is not acidic, in fact it’s slightly alkaline. There, CO₂ can get reduced to ethylene by those electrons.”

The next step was to add a positively charged ion, in this case potassium, to the reaction. This created an electric field near the solid catalyst that made it easier for CO₂ to be absorbed by the surface, giving it the edge in the competition with the hydrogen ions.

The two changes made a big difference. Previous systems typically utilised less than 15 percent of the available CO₂, losing the rest to carbonate. The new system utilises about 77 percent of available CO₂, with more than 50 percent being converted to multi-carbon products.

There are still hurdles to be overcome before this system can be scaled up to an industrial level, including the stability of the catalyst when its size is increased and the need for even further energy savings.

Declaration: A provisional patent application US 63/200,393 titled “CO₂ electroreduction to multi-carbon products in strong acid” was filed on 4 March 2021. Dr Li’s research was supported by an Australian Research Council Discovery Early Career Researcher Award (project number DE200100477).

Hero image: Marcin Jozwiak via Unsplash.